How About Purchasing An Automated Dry Mortar Production Line

If you are constructing a wall, or you are building with bricks, you are going to need to connect everything together with what is called mortar. Dry mortar is what you will need, a substance made of raw materials that can make your brick wall as strong as possible. It has become more popular recently, specifically because contractors are not legally responsible for the quality of the mortar that is being used. Instead, it is the manufacturer of the product that is responsible for how good it is, and people are trying to find ways of getting not only the best deals, but the best quality mortar available. You can find an automatic dry mortar production line in your area to get all of the mortar that you need by using the following tips.

Exactly What Is A Dry Mortar Machine?

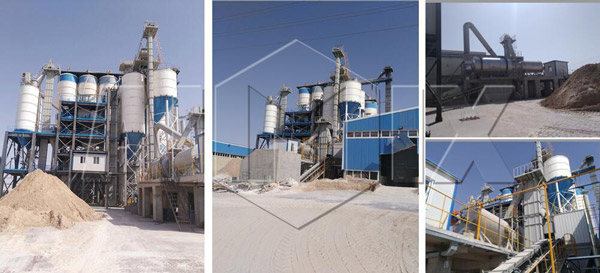

On the basic level, this is a group of machinery that creates dry mortar, also referred to as cement mortar, which can be used by individuals for small projects or large-scale projects within the construction industry. Get details here: https://aimixdrymortarplant.com/dry-mortar-production-line/. These factories are made up of many different components including a power control cabinet, mixing engine, stock been, premix been, and the finished product warehouse. The system functions using a very simple principle. You only hold the mortar inside and paddles on counter rotating spindles causes the aggregate material to spin inside an area, mimicking zero gravity. Once each of the aggregates are mixed together, they will likely become very fluid like, and can mix everything uniformly. All of this is going to be transferred via a pneumatic gate for storage, and may be classified in four different methods.

Classifications Of Mortar

Mortar can in fact be classified within a couple alternative methods. This can include flat, block, stair and tower types. It merely depends upon what the mortar is going to be used for, and exactly how it happens to be produced which is often considered auto, auto manual or even a manual type. Learn more detailed classification at this page: https://aimixdrymortarplant.com/. The mortar will be applied in several different ways including anti-crack, plastering, self-leveling, thermal and what exactly is most popular which happens to be dry masonry mortar. Much like what you would find at the cement or asphalt factory, things are produced like clockwork for that many businesses that surround the factory.

Purchasing An Automatic Dry Mortar Production Line

You can actually find dry mortar production line companies that are selling their factory on the web, and you can also get smaller versions of a large scale factory that you can use on your own. This is beneficial for people that are working a small to medium size business, especially when using a continuous mixer to keep everything viscous enough to pour and use when necessary. As long as you have all of the raw materials to do this on your own such as cement, hydrated lime, limestone powder and sand, you can actually avoid needing an automatic dry mortar factory, simply using a smaller scale unit to use on your own for your business or smaller projects that you are doing at home.

Dry Mortar Plant Manufacturers How To Choose?

You will find different manufacturers of dry mix mortar plants out there. You will wish to understand them in order to pick the best equipment. You will also want to pay attention to the numerous machines available from these manufacturers along with their selling prices. While you take a look at dry -mixed mortar plant manufacturers, you will better be capable of tell what you're searching for around.

Looking at the many machines, I can tell you that we now have a good number of variations. You don't even need to glance at the specs boasting to get that out. Yes, a number of them look similar, but quite a few of them look rather different, too. Some are definitely more compact than others, and one I saw looked want it was a full building. Understandably, it had been a relatively pricey one.

As you lookup the models provided by various manufacturers, you may want to reach out to them to talk about their goods. That's specially the case if you plan on buying on which costs you from the tens of thousands of dollars. It is possible to only discover a lot information online by checking out specs and has. Once you speak with manufacturers, you will be talking to professionals when it comes to these machines.

Dry mortar plant manufacturers should be able to let you know everything you should know. The greater number of traditional mix plants will be the more costly ones. The lesser plants are in fact trending today, and features everything with regards to their advantages. You just have to ensure that you could possibly get enough dry mortar mixes from one of these machines. If you can, then you can definitely rely on a good number of benefits wen you are looking at owning a smaller, more compact machine. Get more info at this website: https://www.zzchangli.com/

You will see tat these plants have special designs, and are generally quite convenient. Unless there is the need for a larger plant, you may also get one of many newer, more modern versions. Yes, you can still find businesses that pay more cash to the enormous plants, nonetheless they have valid reason for needing such large amounts of dry mortar mixes.

You will see tat these plants have special designs, and are generally quite convenient. Unless there is the need for a larger plant, you may also get one of many newer, more modern versions. Yes, you can still find businesses that pay more cash to the enormous plants, nonetheless they have valid reason for needing such large amounts of dry mortar mixes.

What can you be employing the dry mortar mixes for? They may have many different applications, and you can make mix after mix utilizing your smaller, more portable machine. If you believe the compact version of one of those machines can work, then you are going to absolutely love the main advantages of a small dry mix mortar plant.

Take a look at the manufacturers, and then you can decide exactly which one of them will have the plant you want. With the amount of choices, it might be hard to choose. Yet you will be surprised simply because you might see some features that truly stand out. Here is a nice choice for you: https://www.zzchangli.com/dry-mix-mortar-manufacturing-equipment.html

Exploring The Dry Mix Mortar Plant Price

The dry mix mortar plant is a big investment and you want to make sure you are getting the best price if you are going to be investing in one of these plants. One of the best ways to get a good dry mix mortar plant price is to spend time comparing prices that the different manufacturers are offering. You will find a wide range of prices to choose from and you will just have to find the right size plant for your needs.

There are several sizes from which to choose and you must make sure that you get a plant that will big enough to fill all of your current needs. The plant is going to help you make more money since you may get your projects done faster and you can get your projects finished more proficiently when you are utilizing the plant. The plant can produce a lots of mortar quickly and in case you are inside the construction industry this plant is a thing that you are going to want to buy. Learn more at this page: https://www.zzchangli.com/dry-mix-mortar-manufacturing-equipment.html

You may make a huge amount of cash with these plants and so they make producing the mortar so quick which is super easy to acquire what you require when you use the plants. You are likely to need in order to produce lots of mortar if you are in running a business and you need to be able to use the plants to take care of your mortar needs. Mortar is essential in construction projects in fact it is something you need to have if you would like complete your projects easily.

If you use a mortar plant you get to produce all of the mortar you will need and you also are not going to be spending a ton of money to accomplish it either. The plant is a good deal and you can obtain a large amount of work done by using these plants. If you want to handle huge amounts of mortar and you wish to cut costs, employing a dry mix mortar plant a very good idea. The dry mix mortar plant is a superb piece of equipment and it can be used to make more money inside your line of work.

The plant will help you to maximize profits and the price of the plant is worth it. You can find the very best dry mix mortar plant price by online shopping and you will generally get the best deals by doing this. There are several deals available as well as the plant will help you save money and help your work go much faster. Just be sure you spend time comparing prices from your different plants so that you discover the price that is going to work for your requirements the most effective.

You don't want to overspend on your plant and you need to make sure that you are getting a good deal when you are looking for a plant for your business. Making your own mortar has plenty of advantages. Send email to service@zzchangli.com to get more info about the price or Visit www.zzchangli.com

Where To Find A Cement Silo Available For Purchase

If you have been into a cement batching plant before, maybe you are seen the tall silos that happen to be there. These are the containers were the cement is poured after it has been mixed. Things are mixed at the end, and therefore the conveyor belts will require it top. It is poured in through the top side. Once it gets there, it will sit waiting for the trucks ahead and acquire it. While it is waiting, it will likely be churn very slowly so it does not solidify. If you want to get a cement silo available for sale somewhere in China, preferably from one of many top locations, here is where you have to look. Find one at this page: https://aimixdrymortarplant.com/cement-silo-for-sale/

How Many Of These Are You Going To Need?

You will probably need 3 or 4 of these in case you are running a small to medium-size business. It is likely that you might need more for those who have a big business that may be providing not just services for your workers, nevertheless the people you are selling the concrete or cement two. Provided you can choose, try to obtain the ones that are the biggest. In that way, which means you may produce just as much cement as you desire and store it and never have to worry about having orders where you cannot fill them because there is no need enough cement.

How Are These Set up?

These will probably be put in place through a crane. They will lift them into position. They really come fully assembled. They will have legs already welded at the bottom, there can also be a churning device inside. This is going to be operated by some sort of a motor, usually electrical or hydraulic by nature. Once you have found an organization which is producing them, it will be easy to make sure that you receive the best silos for the business. Visit this website to learn more: https://aimixdrymortarplant.com/

Are All Of These Going To Be Shipped Simultaneously?

These are going to be shipped simultaneously in many instances. That is because if you set the order, they are only going to advertise those that they may have available for sale. This means that they are available. After that you can plan to receive them all concurrently. In case you are actually developing a cement manufacturing plant, these will typically include your order. Everything that you will need should come within two or three days. Then you can get busy to set everything up to make the cement and store it from the silos.

Should you be looking for any cement silo for sale, you might want to order several that one time. This is a terrific way to avoid the need to purchase cement from another company that you might charge you substantially more than you are able to produce it yourself. Whenever you can select a business in China which has great deals, you should order as most of them as you have. This may ensure that you may have a good amount of space for storing to be able to reduce costs, and also make the maximum amount of cement as possible for the business.

Sand Dryer For Sale - Here's What You Need To Know

If you're thinking of purchasing your own personal sand dryer, then you're building a great choice. With this guide, we're planning to cover several of the key great things about possessing a sand dryer, and we'll also take a closer look at how to locate a high quality sand dryer for sale. Bearing this in mind, let's get moving.

To begin with, there's no denying a sand dryer is definitely a important machine to possess for specific kinds of construction projects - and it's not unusual to view them used for an array of purposes within many industries. In reality, you'll discover their whereabouts on construction sites, from the chemical and cement industry, and they also surface in lots of other building-related industries. Learn details at this page: https://aimixdrymortarplant.com/.

With regards to fast and convenient drying, it's tough to beat the humble sand dryer. The equipment is generally comprised from a rotary body, along with the raw material feeding plate - and then there's many different props to hold the main body safe and secure whilst the machine is within operation. How big a sand dryer can vary quite a bit, but most often they'll be in the larger side - particularly if you possess a large volume of material to dry.

One of the real benefits of a top quality sand dryer is the versatility. A great dryer will comfortably handle many different types of material - anything from the very best grades of sand towards the chunkier debris that's likely to show up on a construction site.

Now how do these machines work? Well, the typical process is rather simple. The raw materials is going to be loaded in to the machine, then fed into the rotary cylinder with an angled plane (generally a steep angle is utilized to be sure the heavier debris flows down, and only the lighter material is feed into the machine). Click here to learn more.

When the material is here in the rotary cylinder, water and heat is used to separate the type of material even further, because of the negative effects of water vapor that's created. After this separation process, the fabric is quickly dried.

Overall, the procedure is fairly straightforward, which machine is amongst the most cost-effective methods of separating and drying your debris. Another key strength on this machine is the time-tested and reliable design that goes into the development. Currently, you can also buy sand dryers which simply employ subtle vibrational force to function, and also the drive mechanism gives you unparalleled control of a wide array of parameters, like vibration speed, amplitude, temperature, plus more.

So now that you have a little bit more background on which sand dryers are and just how they work, what in case you do when you're searching to pinpoint a sand dryer available for sale? In most cases, it's advisable to start with contacting your neighborhood supplier and discuss your requirements with them. The experienced staff must have some idea in the size you'll need depending on the project you're focusing on, and you'll quickly have the capacity to go to an understanding on whether you prefer to rent or purchase the sand dryer. Visit this webpage to learn more: https://aimixdrymortarplant.com/.

Basic Principles In The Tile Adhesive Manufacturing Plant

Should you work in the building industry and you want to optimize your profit, you may want to buy a tile adhesive manufacturing plant. This plant can produce a lot of adhesive and you will take advantage of the adhesive for your own personel projects or sell it. The plants run automatically and they could help you save considerable time since you can make the adhesive on your own.

You possibly can make a lot of cash if you buy a tile adhesive plant and they are worth the cost. When you are serious about earning money and want to automate the process of making your adhesive, you should put money into the manufacturing plant. The plants are easy to run and they can automatically. You possibly can make huge amounts of tile adhesive by using these plants and they work perfectly. They could make lots of adhesive and you will do a variety of things with it.

The appliance will probably mix within the dry materials and turn them into each of the tile adhesive you can ever need. The device carries a sand drying system that will dry up the wet sand so it will be ready for use in the adhesive mixture. Additionally there is a storage system with each machine which is used to keep the type of material until they will likely be turned into sand. Learn more here.

Each machine also has a hoisting system that lifts the heavy materials and deposits them to the machine. As soon as the materials are hoisted to the machine, the conveying system moves the type of material to another step. Most conveying systems on the machines are belt conveyors. Belt conveyors are really easy to maintain plus they are more efficient.

Each machine features a weighing system that weighs out your correct blend of mortar and mix. After the tile adhesive has been given it is automatically packed with the packing system. The tile adhesive may be stored or packed in bags. The equipment can even be established to pour the adhesive into a truck so it may be transported straight to the task site.

The plants have dust collection systems to help keep the dust out from the air causing them to be environmentally sound. They have control systems that work well automatically or semi-automatically dependant upon the form of system you would like. The device is very dependable and it will create a substantial amount of tile adhesive. Visit this website to learn more: https://aimixdrymortarplant.com/.

If you require tile adhesive and you need to produce it yourself you will want to purchase a tile adhesive manufacturing plant. These are economical and reliable. They can be designed to last and are generally also compact to enable them to fit almost anyplace. You can find room for this and it doesn't take up a great deal of floor space. The adhesive plant is simple to operate and you could make lots of money once you start using one. If you are looking on an economical method to produce tile adhesive purchase a plant.

These Represent The Features Of Dry Mix Mortar Plants

Do you need dry mortar for the construction business? Then, you could have been considering a smart investment in a dry mix mortar plant. If you are not really aware, you will find various kinds of mixes. Using these plants, it is possible to mix a myriad of mortars. When choosing a batching plant, you must know what you're seeking. You know you will need a dry mortar mixing plant instead of one that produces wet mortar.

One benefit mentioned for dry mortar plants is that they don't require this kind of large investment. All mixing plants are pricey enough, however, but the one you decide on will probably pay huge dividends. You will need a mixing plant to your business, and you have decided on this specific type. They last quite quite a while, making this a great investment for your personal construction company.

These plants have many steel parts, therefore they are highly durable. The mixing system for these particular plants is reported to be very efficient, too. Needless to say, you are likely to have to think about the patient models in relation to these plants to enable you to choose the right one for the business. Learn more details here: https://aimixdrymortarplant.com/dry-mortar-production-line/

Another great part of these machines works with the fact that you can count on their automatic processes. Automation is large currently. It could help you save time, manpower and funds. Saving you on manpower helps save a little money. Using the machine operating in automated fashion for the most part, your crew will be able to work elsewhere, getting more done.

The application form array of a dry mix mortar plant is great, too. As said before, you could make all different types of mixes, what you may requirement for each project. Masonry mortars and dry bonding mortars are two exampmles of what you can mix track of the plant which you buy. Exactly what are your immediate needs to get a dry mortar mixing plant?

You are certainly going so that you can trust your equipment lasting quite quite a while. Yet when you glance at the different plants, you're going to would like to know more details on that advantage. Put simply, exactly what is the warranty for one of these brilliant mixing plants? What kind of maintenance is it necessary to do, and where can you get your parts if they are required?

You should know the answers to those questions to help you expect seamless operations. You need to learn how to care for the mixing plant, and you also want to ensure that parts can be found when you want them. Do not forget that one of the main benefits of these stationary mixing plants is the low investment, too. Visit this website to learn more: https://aimixdrymortarplant.com/

Keep that in mind as you are considering prices for dry mortar mixing plants. You would like to produce a solid investment that pays big dividends for the construction business. You might be employing this equipment over and over again, so you want in order to trust the mixes turning out as expected.

Finding The Right Dry Mortar Production Line Price

Because you'll be spending lots of money over a dry mortar production line, you'll want to successfully get a better deal. How will you find the appropriate dry mortar production line price? Once you learn what you ought to try to find, you must find incredible prices and quality products.

Explore The Options

Should you consider lots of different options, you'll be able to find a number of the more inexpensive price points available to you personally. You should spend some time to take a look at different production lines and anything they cost. Try to obtain a deeper understanding of what your options actually are. Here is a recommened website for you: https://chinaconcretemixers.com/

You'll have the ability to discover where greatest deals are if you research prices. Try to look at numerous options and find out what every one of them offer. Try to be careful about how exactly you spend your hard earned money. Sometimes, a small amount of extra research can help you save a lot of money.

Don't Pay Money For Facts You Don't Need

Not every production lines offer the same experience. There are some lines that contain special features. Although these characteristics can actually prove useful, they're not really something you uses.

You shouldn't spend your hard earned dollars on anything that you don't must have. You'll want to take into account how you will be utilising your production line. Evaluate which you want, to check out lines that supply that. You shouldn't spend more unless you're certain that you'll have the capacity to use the features that you're paying for.

Negotiation Using The Seller

The dry mortar plant seller you're purchasing the production line from could possibly be ready to negotiate along with you. In case a vendor is willing to provide an improved deal, you'll be capable of getting what you want for any more reasonable price.

Usually, a seller isn't going to provide a better deal until you request one. You must ask the seller if they are open to negotiations. When they are, you should start talking to them about what you're seeking. They will often provide you with a deal that you'll be happy with.

Buy An Older Production Line

If you opt for one of many newest dry mortar lines in the marketplace, you'll end up spending considerably more. You don't necessarily have to buy among the newer options on the market. If you select something that's somewhat older, you could get what exactly you need while spending less.

Take a look at some older options to see if any one of these choices would have been a good fit for yourself. You could possibly even want to investigate buying a used production line. Buying used items is a superb way to save.

Choosing the best dry mortar production line price isn't always gonna be easy. You'll have to take some time taking a look at a few of your different choices prior to making any sort of decision. With that said, if you're comfortable after the advice above, you should be able to find some terrific deals.

The Key Benefits Of The Tile Adhesive Production Line

If you are looking to grow your organization and you need to create something you can sell and that is going to allow you to money, you should purchase a tile adhesive production line. When you install this compact machine you are going to be capable of produce each of the tile adhesive you require and also the adhesive is going to make serious cash and you could likewise use it with your business. The production line is a reasonable method to design your own tile adhesive and also the prices are right as well. Visit this website, you can learn more: https://aimixdrymortarplant.com/

Tile adhesive consists of sand, cement, and binding agents. If you mix everything together you get a powerful tile adhesive that will be applied from the construction industry. You can utilize the tile adhesive for your very own projects and you may also sell it. The adhesive works well and it is very reliable so you can use it for a wide variety of applications. Should you could require an excellent adhesive, you can't get it wrong using a quality tile adhesive because it works so well.

The adhesive is easy to use in a wide variety of ways and is particularly also easy to help make. The machine will almost certainly do everything and you just get to chill out and like the profits. The equipment works automatically and it takes the constituents from the raw state to the finished state. The controls are easy to operate along with the machine is loaded with security features which means you don't need to worry about anyone getting hurt when they are dealing with the equipment. Get the details here.

The machine is not hard to work and you could train your workers quickly and suggest to them how to use it. The device doesn't create a great deal of dust or debris and it is an environmentally correct way to create tile adhesive. The tile adhesive is going to work very well and it will adhere virtually any form of tile. Tile adhesive is vital if you are operating in the development industry which machine can be something you will want in the event you work in the development industry.

The adhesive is incredibly strong and it is gonna work great to create your projects turn out below budget. You reduce costs whenever you make your own adhesive and you also don't ought to source it in other places. It will make your life easier and you could even earn more money once you have a tile adhesive production line. If you require adhesive it just is sensible to acquire your very own adhesive so that you don't need to spend so much cash on buying it from another vendor.

The adhesive production lines are something you should buy and it also is going to make your work easier and help you save money. When you want to save cash and you will need a machine you can trust, you are going to want to purchase an adhesive production line.

Self Loading Concrete Mixers And Their Different Applications

Self loading concrete mixers are made to deliver exceptional performance in various fields. You can use it for your construction and excavation of tunnels and mines to varied urbanization projects. All machines can easily be modified to every single possible use and requirement according to the application. Here are one of the applications that the mixer works extremely well.

Construction And Excavation Of Tunnels And Mines

Inside a complex activity like mine construction, concrete materials work most effectively possible support for building load-bearing pavements, buildings, rocks, ducts, and canals owing to its resistance to nature and suppleness of use. The solid material also lends itself to assist tunnels that are excavated in delicate rocks to give it stability and fill out the holes and cracks to avoid water infiltration. Using concrete being a cover can be a technique most importantly working in the excavation and construction of tunnels with large cross sections and more complex structures. Self loading concrete mixers are fundamental in most geological conditions for reaching probably the most sensitive areas and tackling the bumpiest ground. Visit this website to learn more: https://chinaconcretemixers.com/

Fabrication Of Bridges, Railways, And Roads

Fabrication Of Bridges, Railways, And Roads

Concrete pavements have got a longer lifespan that other construction materials and the requirement for preserving its condition are far lower. Bridges, railways, and roads may be built directly on-site using mixing machines that act as mini mobile plants capable to break any ground. Concrete materials are best for building these structures as it is resistant against alterations in temperature.

Construction Of Buildings

Concrete is the greatest material to be used for constructing industrial or residential buildings because it resists any compressive force. This is why it is vital to utilize concrete only created using a rigorous and excellent mixing process, which happens to be exactly what a concrete mixer guarantee at each and every construction site.

Foundation And Ground Consolidation

All kinds of mixers lend themselves to the construction of foundations, piling, and land consolidations. Their operations must be completed with perfect precision to be sure the stability of all the structures. Learn more details here: https://chinaconcretemixers.com/self-loading-concrete-mixers/

Precast Concrete

The concrete created by a mixer makes possible to get high-quality precast products to be used in lots of projects, from impressive buildings to landscape architecture. The molds accustomed to make these precasts can be re-used an unlimited amount of times, and they offer cost-effective and efficient constructions in every varying weather conditions.

Urbanization Projects

Concrete mixers are fantastic for constructing most straightforward structures like airports, bridges, buildings, roads, sections, and slopes, where their excellent resistance and performance will be required. After these structures have performed their task for that they can were built, the concrete materials employed to create them may be crumbled and recycled to become a filler or roadbed for new pavements.

Generally speaking, these self loading concrete mixers with truck can save a lot of labor work than using manual concrete mixer machines. Their operators will have a comfortable and safe operation environment. With all the efficiency and safety of those self loading mixers, they are likely to receive more significance in the construction industry than before.

Methods For Investing In A Dry-Mix Mortar Plant

Buying a dry-mix mortar plant is practically a routine purchase. You can accomplish it online and possess the equipment delivered and installed wherever you want it. However, this requires a good knowledge of the machine you require, as well as a careful collection of the supplier. The following tips may end up being valuable in your endeavor to get the best equipment your cash can purchase. Visit this website to learn more.

One thing to do would be to decide on the principle features and technical specifications of the dry-mix mortar plant. You don't need to be very specific, but you have to know some boundaries in the various parameters from the equipment. Similar to this, you'll have the capacity to contact the sellers and to ask them to get a more accurate price quote instead of a general one. You'll also have a solid ground for a side by side comparison of the available options.

The best method to prevent comparing apples to oranges will be very specific if you ask potential suppliers for a quote on their own equipment. As possible easily imagine, these quotes may vary quite a lot, making comparison difficult. When you know your needs, you can pick the right option that gives you everything that you need at the best price. These mortar plants are available in different sizes and have different productivity rates.

It would be unfortunate to purchase the one that can't manage your needs in terms of capacity. At the same time, buying equipment that exceeds your requirements certainly is a total waste of money. You'd have to spend an increased amount to buy equipment you're not going to use at its full capacity. Seeking the middle approach is factor to a successful purchase. More details here.

Regarding finding suppliers, a Internet search will disclose a lot of names to choose from. Most manufacturers of those industrial equipment have compelling websites. Even China manufacturers have their own own websites targeting international clients. You'll also find lots of businesses in marketplaces like Alibaba and eBay. In fact, buying your equipment from China is probably not this type of bad idea. These manufacturers are as reliable as may be, they may provide the high quality quality you anticipate, and they have the appealing factor for being more affordable than their American counterparts.

Prior to your decision, though, you should try to learn anything you can regarding the companies in your shortlist. Their experience in addition to their portfolio of customers are perhaps the main details. Furthermore, you must figure out the opinion of the other clients about their products and approximately their post-sales services. This isn't too readily available out, as you'd need to ask all of these contractors for customer references. Nonetheless, although it will take a significant while, this is certainly worth doing, mainly because it will answer all your questions in regard to the professionalism, the punctuality and also the attitude of the sellers.

Every one of these tips needs to be enough that you should choose the right tile bond making machines to suit the needs of your organization and yo keep the clients pleased with the services you provide.

The Best Places To Get A Dry-Mixed Mortar Production Line

Investing in a dry-mixed mortar production line could be the beginning of any very lucrative business. You only need a trusted supplier to offer you the machine, a location to put in it, and enough clients to generate a nice profit This articles takes a good look at finding the needed equipment.

Fortunately that you can get your dry-mixed mortar production line online, without even having to meet the seller face-to-face. In case you are interested in visiting a human face, you could always get a Skype conference chat. Because you don't need to travel to meet the supplier allows you to expand your quest to remote countries and territories. Why not buy your production line from the China manufacturer and get it delivered to an address of your choosing?

The one thing you have to concentrate on is to locate a really trustworthy supplier. Otherwise, there's no doubt you're likely to find lots of manufacturers of those equipment. Simply use your chosen google search and find out what you are able get. Check out stand-alone websites of companies advertising on top of the results pages, but don't overlook small business listings. These ones are usually very detailed, since their owners are willing to go that step further to have potential customers contact them for any price quote. Click here to learn more.

Companies that list their equipment in global trading directories also can come up with a great option. Some of them might be in China or India, but this doesn't mean you can't get your mortar production equipment from their website. Just check their background, their experience along with the quality standards they apply in their factories. Also make sure they will provide you all of the support you're likely to need during installing your equipment. Some operator training would also be welcome.

Before proceeding to this research, you have to know what you're searching for regarding capacity of your production line. You must write an organization plant, in order to estimate what number of mortar you'll must deliver per day, and many other important highlights of your equipment.

Each one of these being said, the ideal supplier isn't necessarily the one that provides you with the machine you need on the best price in the marketplace. You can't forget about the added benefits that might help you utilize your equipment to the full and provide your own personal clients the very best-notch quality services they expect.

As you can't know for sure whether a supplier can live up to your quality standards, you must determine an indirect may to examine how good their products and services and customer services are. Contact those which can sell you the equipment you will need and make them offer you a couple of customer references. make contact with their other clients to find out first hand how reliable and professional these suppliers are. Visit this website https://chinaconcretemixers.com/ to learn more.

This way, you have great chances to discover a reliable contractor to market you high-quality equipment that's gonna contribute to your very own success.

What To Consider In Dry Mix Mortar Plant

The dry mix mortar plant is certainly a useful machine when you really need to create a lots of mortar inside a short amount of time. This plant can assist you in a variety of ways plus it will help you produce all the mortar you have to go far together with your work. The plant is affordable and you can easily use. It is something you need to have if you are planning to get employed in the property or construction industry.

Construction is actually a competitive field and it is crucial that you make time to look for the right equipment. There are plenty of several types of equipment you are going to need if you are employed in construction and you also want to be sure that you will be using the right sort of equipment. Click here to learn more.

When you know by pointing out different kinds of equipment you are likely to have an easy time buying the right equipment. You need to be sure that you are able to handle the equipment such as you are supposed to and it is very important deal with your dry mix mortar plant so that it lasts so long as possible. You may get a lot of use using this plant and it can assist you in making more income. The plant will likely help you to get your work done faster and will also streamline production.

The plant is constructed from the best materials in fact it is created to last for a long period without having any maintenance. The machine is simple to use and this will help you get more done. You might need one of those machines if you want to produce a lot of mortar along with the machine can help you in a lot of ways. Should you be prepared to produce large amounts of mortar you must spend money on one of these machines so you can make each of the mortar you will need. Visit this page to get the details: https://aimixdrymortarplant.com/dry-mortar-production-line/

The machines let you produce huge quantities of mortar and it also will be easy to produce the mortar you want when using one of these simple machines. The right machine is going to make it much easier to obtain a lots of work done and your profits will go up once you begin to work with the machine. These appliances help it become quite simple to complete more work and they can assist you deal with all of your orders and projects.

You can work faster once you have the correct equipment. Good equipment will help you get to work faster and when you work faster you are likely to make far more money. You must make an effort to make all the money as you possibly can and also the best equipment will help make which happen. The right equipment is well worth the investment which is just what you ought to work faster and earn more money. You have to be sure the device is big enough to meet your needs. Visit this page to get more ideas: https://aimixdrymortarplant.com/wall-putty-manufacturing-plant/

Discovering The Right Dry Mortar Production Line Price

Because you'll be spending a lot of money with a dry mortar production line, you'll want to ensure that you obtain a good deal. How will you find the correct dry mortar production line price? Once you know what you should try to find, you must find incredible prices and quality products.

Explore The Options

If you consider a lot of different options, you'll manage to find several of the more competitive prices that exist for you. You must make time to examine different production lines and anything they cost. Try and gain a deeper comprehension of what your options actually are.

You'll have the ability to find out where the best deals are in the event you shop around. You need to take a look at numerous options and discover what all of them offer. Try to be careful about how you spend your hard earned dollars. Sometimes, a small amount of extra research can save you lots of cash.

Don't Purchase Items You Don't Need

Not all production lines offer the same experience. There are many lines that are loaded with special features. Although these characteristics will surely come in useful, they're possibly not something that you uses. Get more details here.

You shouldn't spend your cash on whatever you don't actually need. You'll want to consider how you are likely to be utilizing your production line. Decide what you will need, and check out lines offering that. You shouldn't spend more money unless you're certain that you'll be capable of take advantage of the features that you're spending money on.

Negotiation With The Seller

The owner you're acquiring the production line from could be happy to negotiate along with you. If a vendor is willing to provide you with a better deal, you'll be able to get what you need for a more reasonable price.

Usually, a seller isn't going to provide you a greater deal until you ask for one. You need to ask the owner if they are accessible to negotiations. When they are, you need to start speaking to them as to what you're searching for. They could provide you with a deal that you'll be happy with.

Buy An Older Production Line

If you buy one of several newest dry mortar lines available on the market, you'll wind up spending far more. You don't necessarily should buy among the newer options on the market. In the event you opt for something that's a bit older, you can get what you need while being economical.

Examine some older options and find out if these choices will be a good fit for yourself. You might even want to examine purchasing a used production line. Buying used items is a wonderful method to save. Visit this website to learn more: https://chinaconcretemixers.com/

Discovering the right dry mortar production line price isn't always likely to be easy. You'll need to take some time taking a look at a few of your different alternatives prior to making any kind of decision. Having said that, if you're comfortable after the advice above, you will be able to find some terrific deals.

Allow Me To Share The Reasons Why You May Want A Dry Mix Mortar Plant

There are actually different types of cheap dry mortar mix plants out there, plus they have different features. One important thing you will find is many of them feature computer batching systems. This helps automate much of the processes which are associated with by using these production machines. You might also wish to look more closely on the products you possibly can make with dry mix mortar plants, too.

By way of example, you are able to trust having the ability to make cement grouts, tile joint fillers, stuccos, thin joint mortars and much more. There are actually a myriad of products as mentioned, and you will need to make a note of what exactly you need from one of those machines. Why count on a dry mix mortar plant to help you complete your construction projects?

The sustainability in the mixes you will make have much to do with why you may want one of these brilliant machines. This is why many construction companies on the market wish to them in order to get better quality materials that don't require much maintenance. While that is obviously a plus, you should find out more regarding the benefits before you purchase this type of machine. Learn more about it here.

What else can you trust when it comes to advantages when you have a dry mortar mixing plant for the company? You might realize that you could rely on reduced shrinkage, and you will also rely on better hydration. That is certainly certainly a benefit in case you have one of these simple plants.

Did you know that you may use one of those plants with regards to masonry? That's right, and you will likewise use these products from their store to help you fix tiles. Perhaps you have used a plant that mixes dry mortar before. If you have, you may not be as informed about the better modern versions of the plants. You should check into all of their features so you are aware what to anticipate whenever you purchase a mixing plant.

Once you decide to purchase a dry mortar plant, is it necessary to buy a replacement? You may want to know if you can to obtain a discount over a used machine. That might be nice, but you will need to make certain that you aren't sacrificing in terms of the functions you will need from one of these machines.

Now you can check out the dry mortar mix production equipment to see precisely what you require. There are numerous companies available designed to use these appliances, all over the world. There are many clients which use these products these machines make or rely on the type of material being used on his or her projects. Visit this website to learn more: https://www.zzchangli.com/

If it's time for you to start looking at buying one of those plants, reach out to a trusted manufacturer for any quote. Then you can decide if you are intending to advance forward with investing in a plant that can mix dry mortar products. Then you could start to look at what you ought to must make those mixes.

How To Find A Dry Mixed Mortar Production Line

Looking around for any dry mixed mortar production line is easier than you think. You don't must travel or hire specialists to locate you the equipment you will need. Thanks to the internet, buying heavy machines and industrial gear is now incredibly easy before. Here's what you should learn about that.

One and only thing you need so that you can start in search of suppliers can be a computer or possibly a smartphone connected to the internet. You should also know what you wish regarding features and technical specifications of your respective ideal dry mixed mortar production line. There are lots of types of such plants, so knowing what you would like can assist you limit your alternatives right off the bat, making it possible to keep your valuable time. Think about the productivity, the packaging, the storage along with the handling of your respective end product, in order to assess your preferences as accurately as possible.

This will also enable you to get the best value for money. Should you just purchase the biggest and the most powerful production line you will find, you might never utilize it at its full potential. Why pay so much for items you don't need? Concurrently, buying a really small plant may end up being inefficient in relation to satisfying the requests of your clients. You must discover the equipment that permits you to have the productivity you need, whilst offering some room for growth.

As soon as you things to buy, the next task is to browse online for manufacturers of the equipment. Take a closer look at their websites and choose those who have good credentials, an extensive experience available on the market plus a solid work portfolio. At the same time, hunt for client reviews, because they are the mirror from the supplier's professionalism. Unfortunately, such information might be hard to locate in some situations. The most effective workaround is always to contact those manufacturers and request client references. More details here.

If you also want to locate an affordable price, you must expand your search area with other continents. There are several equipment manufacturers in China and India who can provide you with the same high-quality production lies as your local contractors, but at a far greater price. His or her countries are less costly, they could still produce a profit, making this a winning situation for many parties involved. You can get such manufacturers in global marketplaces like Alibaba and Aliexpress.

Besides, thanks to their in-built escrow system that handles all payments, your transactions will likely be as safe as can be. You'll make the payment, although the money won't make it to the seller's account at this time. They will likely ship the order, realizing that you've paid for it. Next, once you receive the goods and you confirm that things are fine, the payment is released plus it reaches the serller's banking account. This will make buying industrial equipment from China a cinch, to the main advantage of small enterprises like yours who can't invest a ton of money in assets and tools. Visit this website to learn more: https://www.zzchangli.com/.

Self Loading Concrete Mixers - What Makes Them The Ideal

Self loading concrete mixers are the largest and most powerful agitator trucks out there. They provide powerful engines, plus they are also known for their benefits. You may have already guessed that this machines actually feed themselves, and they also measure and mix all on their own, too. It basically looks like they do it all, right?

These are an all-in-one machine for sure, and they can basically do it all. Once you consider the models, you will notice that they typically have four wheel steering. That can help and possesses everything to do with these appliances being powerful and able to carry heavy loads. You are going to have the capacity to make reliable mixes, and you may count on the flexibility of your machine.

What you can also trust in relation to this machine would be the fact it may carry all of your raw materials. Isn't that great? Usually, you need to mix concrete and accept it towards the job site, which can be perfectly. Yet it could have to be diluted when you are stuck in traffic. By using a self loading mixer, you may rely on having the capability to perform the mixing with the job site if you want. Learn more details here.

You merely transport the raw materials around the web page, and you can trust the mixer doing everything when you get there. Would you even need to lift a finger? Self loading concrete mixers seem great, don't they? You are going to like the fact that you have a machine that does it all.

Yes they do cost a little bit more compared to other agitator trucks on the market, but you are really planning to enjoy having such a great mixing truck readily available to assist you. When you are ready to discover what all one of these brilliant mixers can perform for you, then you certainly will be in for any treat. These powerful machines make mixing concrete look like quite the simple job.

And remember, you have all kinds of mixes you could make. This machine does that meet your needs, and it's likely to be quite the operation. Make the way from job site to job site using the mixes how the truck prepares. You are likely to have the capacity to rely on quality mixes, as being the self loading mixers are said to be very reliable. You are certainly looking for a reliable mixing truck as you get willing to take your operations mobile. Visit this website to learn more: https://www.zzchangli.com/

Price the self loading mixers to view the direction they vary from other agitator trucks. Maybe the purchase price difference won't be a lot, and you could certainly take a look at used trucks, too. Once you determine what you are looking for, it's likely to be great putting that truck to work. All you will have to do is simply provide the machine what it really needs, and after that it takes care of the remainder of the process all by itself.

The Different Types Of Concrete Mixer With Pump

The basic purpose for the concrete pump is to use it to transfer liquid concrete via pumping. To get this done and ensure that the pump is suitable for your construction project, you should remember that the mixers can be purchased in different machine sizes however, the larger industrial mixers are usually utilized for construction sites. This can be simply because that industrial concrete mixers with pumps are created to feed concrete to construction areas quickly. This information will discuss both different types of concrete mixer with pump models - the boom pump and also the line pump.

1. The Boom Concrete Pump

You can find typically 2 types of concrete mixing pumps for use - the boom concrete pump as well as the line concrete pump. The boom concrete pump is a large machine presenting using a boom arm to keep the size of runner tubing in which cement will flow towards the required position on the construction site. A boom concrete pump can pump concrete at approximately a vertical reach of 65 meters along with a horizontal reach of 300 meters. The duration of the boom determines just how far away the truck will probably be placed and also the distance whereby the concrete will have to be pumped. The truth that the pump is positioned far from the building site helps make the mixer a good choice for pouring concrete in high-rise or multi-storey construction sites.

When selecting a boom concrete pump, you have got to select from the truck-mounted pump and also the trailer-mounted pump. The trailer-mounted boom concrete pump utilizes an articulating arm and places the boom constantly in place to position cement where it really is needed. This kind of pump is actually a high good value alternative and can be utilized on the majority of larger construction projects as they could pump high volumes of cement. Also, they are labor-saving options due to placement of the boom to a specific location. Learn more details here.

The truck-mounted pump is also cost-effective plus more beneficial because of its plethora of boom lengths. This kind of concrete mixer presents with booms of various sizes which is easy to get a mixer with a 3, four to five-section placing boom. Consequently there is the choice of a "z" fold, "multi" fold or "roll fold within the machinery which makes them very easy to manoeuvre and conform to even the most restrictive construction sites. Some of these truck-mounted pumps, particularly those in the smaller concrete truck, are powered by their very own engine which makes them highly economical.

2. The Concrete Line Pump

The concrete line pump is a kind of concrete mixer that is utilized for smaller construction projects in comparison with boom concrete pumps. The line pump is far more beneficial being a smaller bit of machinery as it is versatile, mobile, and enables you to pump both structural and wet items. The line pump typically uses a ball-and-valve pumping system with low-volume output thereby, it pumps lower volumes than boom concrete pumps which is useful in residential building projects. Visit this website to learn more.

The Key Advantages Of The Concrete Mixer Pump

If you want equipment that you can rely on, you wish to consider buying equipment to your manufacturing business such as the concrete mixer pump. This pump is certainly a useful device and it will help you work a lot faster. The pump will almost certainly last for some time with little maintenance plus it works hard to provide the outcome you would like. This pump is simple to operate and it is reliable so you don't have to worry about downtime.

When you find yourself ready to invest in a pump you should take some time comparing prices so you know what you want to buy. There are several models to select from and also you want to be sure that you find yourself buying the right model for your personal budget and your needs. It can be difficult attempting to find the best pump and you should hang out seeking what exactly you need so you find yourself with all the right model.

Take the time to compare costs because taking this extra time will almost certainly help you save money and you will know how to get the best deal when you compare pumps. The ideal pump will help you make more cash which is also going to assist you finish your jobs faster which is going to make you more income down the road. You would like to try to make all the money as you can and when you make more money your organization is going to be more lucrative. Get more details here.

You wish to try and make all the money as you possibly can and also the right equipment will make earning money a lot easier. You must have the proper equipment to make money of course, if you don't choose the best equipment your workflow will almost certainly slow way down. When you really need lots of concrete quickly you desire to ensure that you pick the best mixer pump.

This pump will assist you to make unlimited quantities of concrete and also the pump is going to work quickly to actually will make every one of the concrete that you require. This pump is incredibly efficient and it may produce a huge amount of concrete quickly. When you want a great deal of concrete you want to invest in one of these simple pumps so that you can make each of the concrete you require. The right pump will help you obtain your jobs done faster and it also will likely be easier to have all of your work done.

You can get the best pumps online but be sure that you get the best price. Spend some time comparing prices for that concrete mixer pump and make certain to obtain the lowest price. In addition, you need to make sure which you invest in a pump that can handle the quantity of concrete you need to mix. The proper pump will help save you a ton of money and this will help you make money. Visit this website to learn more: https://www.zzchangli.com/

How To Locate Reliable Dry Mortar Production Line Manufacturers

Establishing a dry mortar production line is most likely the beginning of your very lucrative business. When you can get a few regular clients, you may make a great living using this. However, you should be aware that finding the optimum equipment and machines isn't always the easiest task. This post shows you how to discover reliable dry mortar production line manufacturers.

Fortunately that most industrial equipment manufacturers come with an online presence today. They already know that their potential customers are online, therefore they invest money and energy into creating awareness for goods and services in search engines and also on social networking. This simply means a straightforward online search will reveal lots of potential partners, so you'll be able to find some dry mortar production line manufacturers to pick from. The point that you're going to find plenty of options right off the bat doesn't imply that you should go for the 1st supplier that comes your path. You must compare multiple offers, to be able to obtain the ideal deal.

Furthermore, you need to eliminate all suppliers that aren't reliable. It is a very improvement part of your quest process, which means you shouldn't overlook it. Always collect just as much information as you can about all equipment manufacturers on the shortlist. Those who have already been with this busienss for at least 10 years are probably trustworthy and professional. They wouldn't have made it in such a competitive market should they weren't reliable. However, this doesn't exclude young companies. You can add probably the most interesting ones for your shortlist for additional background check. Learn more info at here.

Remember that the simplest way of finding out what to expect coming from a certain supplier is usually to make contact with their former clients. This is a great opportunity to inquire further everything you need to know about that manufacturer contributing to their equipment, their customer support teams, along with their technical staff. Most manufacturers would give you some client references immediately, as they know it's within their interest that you contact these customers. Should they don't want to offer you this info, you ought to probably ignore them and proceed to the next supplier.

If you are interested in performing solid background customer research, you may safely choose providers from your portion of the world. You might even consider using a China company. Most of them as as reliable as might be. Besides, they usually have top-notch equipment at reasonable prices. This makes them a viable choice, so don't leave them aside on your consumer research stage.

They can be not too difficult to check on, since they list their products and services in global trading directories such as AliBaba. These directories publish client ratings and reviews for those their listings. You'll be capable of see instantly whether a specific supplier has good ratings or not. Always stay away from the people with poor reviews and you'll be in the safe side in regard to the selection you're will make. Visit this website to find some nice ones.

Have you got an automated dry mortar production line

Have you got an full automated dry mortar production line that may be currently operating at the facility? This can be a product that is in high demand, specifically in cities where walls, buildings, and many other structures are put up. This really is the substance that is utilized to set down tiles and a variety of other indoor product installations. It is in high demand, and if you can get a reliable automatic dry mortar production line that you can purchase, this might change things to your business. To gain access to every one of the mortar that you want, and you have extra that you could sell, it's really likely to help your organization grow.

Where To Start Your Quest Of These Businesses

The companies that can produce all of this for yourself are likely to be highly revered by other businesses just like you. The truth is, they may be probably purchased these production lines from these same companies before, perhaps for several years. The ones in China might be the best choice. The firms there can produce these to get a minimal amount of cash and this means you may pay less for any superior product. Your research must always begin online, gradually leading anyone to websites which can be selling them plus online international classifieds.

Would It Really Need To Be Fully Automatic?

These needs to be as automated as is possible. In fact, should they be not fully automated, it could stymie your skill to take on new customers. When human intervention is essential, this might slow your production line and force you to fall behind on all of your current jobs. In most cases, when you are dealing with mortar, cement as well as concrete, automation is extremely important to having an effective business. You just need to turn everything on, properly distribute the constituents from the mortar you are making, along with the machine will do the rest. Get more details about it here.

How For The Greatest Automated Mortar Making Machines

A few of the mortar making machines that you will discover will most likely be overseas. Specifically, if you need the very best deals, that's where you should go. In countries like China, they are constantly making upgrades to every single item that they generate for your industrial marketplace. Of those, mortar machines have become more automated than previously making it easier for even newbies to operate them. Just be certain that it must be big enough to provide you with the mortar that you will require. If you can do this, you will be on your journey to higher numbers of profit for the business.

The automatic dry mortar production line which you purchase needs to be the result of many hours of research. You must know that it is coming from a manufacturer that is considered reliable. Whenever you can verify this all, you will be aware that what you really are purchasing is constructed to last. Above all, it will likely be a piece of equipment that will operate for quite some time, usually overproducing the mortar that you uses to help you have extra that one could sell. You can visit this webpage to learn more details about it.

Dry Mortar Production Line Facts

What does a dry mortar production line do? What are the materials utilized in the production process? How expensive is it to put together a production line?

A dry mortar production lines are the gear employed to produce dry mortar for construction companies and industry. It creates the powdered mortar that is then mixed to help make mortar utilized in homes, office, and building construction worldwide.

The gear includes group of tanks holding the different materials required to produce the mortar. It ought to be noted a full production lines are usually capable of making many different different types of mortar. Learn more about it here. The many mixes works extremely well in numerous applications. Thermal mortars are being used in applications where insulating properties are necessary. Decorative mortars are created using pigments to generate colorful mortar. Standard masonry mortar is utilized for laying bricks as well as other masonry projects.

Each different type of mortar needs a bin to carry materials for that mix. The dry mortar production line dispenses the correct mixture of material in to a mixing tank where some paddles constantly mixes the dry materials to create a level blend. Materials has to be perfectly blended to be certain every bag of mortar is consistent.

This mixture bin then dumps the dry mortar mix into a storage bin, where is is held until packing. The dry mortar then is relocated to the packing line where it really is placed into bags, stacked with the stacker, and ready for shipment. An essential component throughout the entire process is dust collection. The dust collectors help keep the dry materials from dispersing through the area and being a hazard to operators and also the vicinity. Click here to learn more.

The production line requires much space for setup. You must plan carefully to permit space for trucks delivering raw materials and trucks taking the packaged mortar to your customers.

Dry mortar production lines can be bought for a starting price around $24,000 to prices well over $100,000. The retail price variations be determined by the size of the line, the quantity of storage tanks, and other options. Remember, this really is is the expense of the fundamental line and will not include shipping, setup, as well as other costs to produce the production line ready to run.

Dry mortar production can be a dirty business. The powder materials can certainly make a mess despite having a well designed dust collection system. You need to plan on a good amount of cleaning. Employees should wear protective masks to maintain dust from entering their lungs.

Whilst the business will not be inexpensive to arrange, and comes with a dirty side, this is a solid business. Mortar is constant demand by construction companies, local contractors, and folks doing home remodeling. Visit this page to get more info. Top quality mortar is usually on the go. Provided you can hold the capability to make specialty mortars, the demand and profit margins for your product increase.

A dry mortar production line could possibly be the start of a fresh business, or a great way to expand business for someone already inside the construction industry.

Talk with dry mortar production line manufacturers

Talk with dry mortar production line manufacturers to look into which plant best suits your organization. Do you have worked with dry mortar mixes before? You can find all sorts of mixes that can be produced if you use one of these simple plants, and as you can imagine, they can be suited for a large collection of projects. There are actually smaller plants and production lines, and you can also find rather large-scale plants that costs a multitude of dollars.

Take into consideration what sort of dry mortar mix production line you need for the business. Population growth around the world as well as the uses of these mortar mixes has prompted owners of companies to buy these production lines. When you are considering the mortar mixes that one could produce, are you currently considering dealing with more construction bids like a company using this type of machine available?

You would like your investment to settle for certain. Perhaps even a compact mortar mix plant would fit your business perfectly. If so, you might pay lower than $5k and get a plant that handles everything in terms of your projects. These automated machines can perform a lot, and are generally creating products which can be used in construction because of the durability.

The longevity of these mixes is essential to bring up since they require far less maintenance. In case you have materials that are long-lasting, that has a positive change about the environment as well. What kind of impact are these dry mortar mixes having around the country where you live? The content I'm reading at the moment provides extensive details about India and exactly how the dry mortar mixes are employed there in a major way. Get more details about it here.

The truth is, the craze is anticipated to go on. If you feel you are seeing the identical trend where you reside, then you are likely to wish to purchase one of these brilliant dry mortar mix plants so that you can grab the numerous mixes utilized for certain types of projects. Just what is the alternative solution?

When the alternative solution to these dry mixes is a material that isn't as cost effective, then maybe you are about to create the right investment. You want the structures you build to be of your highest standards. This means you will need materials of the very best quality, and you could produce your own dry mortar mixes where you do business. Are you going to buy one of the machines to help you deal with that in-house? Visit this website to learn more.

If you have, it's time to speak with a dry mortar production line manufacturer to help you obtain a quote. Charges are listed for such machines, but they are listed as price levels. That doesn't mean you can't first pick out a certain model. Once you find the model and value range that you're trying to find, then you can certainly talk with the producer in regards to the specifics and what you are going to must pay to the plant that you would like.

Finding The Right Dry Mortar Production Line Price

Because you'll be spending a lot of cash on the dry mortar production line, you'll want to ensure that you obtain a good deal. How could you find the appropriate dry mortar production line price? Once you learn what you need to search for, you need to find incredible prices and quality products.

Explore Your Choices

When you consider a lot of different options, you'll be able to find a few of the more inexpensive price points available to you. You should take time to examine different production lines and anything they cost. Try and gain a deeper comprehension of what your alternatives actually are.

You'll have the ability to determine the location where the greatest deals are in the event you research prices. You need to have a look at a variety of options and see what every one of them offer. Be careful about how you spend your money. Sometimes, a little bit of extra research can save you lots of money. Find some nice ones at this page.

Don't Purchase Things You Don't Need

Not all production lines provide the same experience. There are some lines that contain special features. Although these functions can actually come in handy, they're not necessarily something you will use.

You shouldn't spend your hard earned dollars on something that you don't actually need. You'll want to think about how you are going to be using your production line. Determine what you want, and check out lines that provide that. You shouldn't spend more unless you're confident that you'll have the ability to use the features that you're paying for.

Negotiation With The Seller

The seller you're getting the production line from could be prepared to negotiate with you. In case a vendor is willing to provide you a greater deal, you'll be able to get what you would like for any more reasonable price.

Usually, a seller isn't going to provide you with a better deal until you demand one. You must ask the seller should they be available to negotiations. If they are, you should start talking to them about what you're trying to find. They could offer you a deal that you'll be at liberty with.

Buy An Older Production Line

If you buy one of many newest dry mortar lines out there, you'll find yourself spending far more. You don't necessarily must buy one of many newer options in the marketplace. When you select something that's a lttle bit older, you can get what exactly you need while spending less.

Take a look at some older options and discover if some of these choices would have been a good fit for yourself. You might even want to examine investing in a used production line. Buying used items is a superb method to save. Visit this website, you can find what you want.

Finding the right dry mortar production line price isn't always likely to be easy. You'll need to take some time considering several of your alternative ideas before you make any kind of decision. Having said that, if you're comfortable following the advice above, you should certainly find some terrific deals.

A Review Of Tile Adhesive Making Machines

Today's homeowners and companies are utilizing tile in additional ways than in the past. From commercial flooring to decorative wall treatments, tile may be used in many alternative methods to produce buildings more functional plus more attractive. You will discover tiles which can be constructed from a variety of materials including ceramic, porcelain, glass, and natural stone. One thing that all of these tiles have in common is that they require an adhesive in order to be installed.

While there are many of different types of adhesives that you can use, thin set mortar and other similar adhesives are often typically the most popular. Not only are they extremely durable however they are also easy to use, leading them to be a great selection for numerous applications.

The excitement of tile presents an original opportunity for savvy entrepreneurs. Investing in a tile adhesive making machine can allow you to take advantage of the tremendous potential on this ever-growing market. By manufacturing and selling high-quality tile adhesive, it is possible to position yourself for financial success.

The great thing is, adhesive making machines for tile are relatively affordable and are really easy to install and operate. While they come in many different sizes, they can be usually quite compact. Because of this you don't need much space to put them up or operate them.

You will discover small, simple machines which can be manually operated, at least to some extent. Larger, more advanced machines usually automate the adhesive making process, minimizing the quantity of laborers required. If you are only starting out, you may want to start with purchasing a small to medium-sized machine. This will give you the opportunity to gain some traction in the business as well as to establish a subscriber base. Once you start to get consistent orders, after that you can upgrade to some larger machine. You can click here to leran more.

Should you do plan to purchase one of these brilliant machines, you ought to make use of a well-known, trusted manufacturer. With any business, ensuring your success hinges on the caliber of the device that you just own. If you purchase a small-quality machine, you almost certainly will come upon lots of problems. This will make you not just hang around but also generate losses.

Purchasing a high-quality machine, alternatively, helps ensure your workflow doesn't get interrupted by unexpected breakdowns or other problems. For that reason, you can turn a much more consistent profit. Perhaps more importantly, you may also consistently meet the needs of your own customers, helping to ensure they are fully satisfied.

Since the popularity of tile continues to grow, it is the right time to purchase a tile adhesive making machine. Buying one of these machines will assist you to start making and selling your own high-quality tile adhesive. With such a sizable market, you shouldn't possess any trouble finding customers. Having so many potential prospects also provides a great deal of room for growth. That means that it is possible to take your small business so far as you are able to go so long as you invest enough time and energy. You can visit this website to get more info you want.

Dry Mortar Production Line Prices Are Determined By Manufacturer And Setup

When you invest in a Dây Chuyền Sản Xuất Vữa Khô, you might be making quite the important buy. Obviously you do have a policy for that investment. While that's the situation, have you seen the actual size of these plants? In general, you're discussing six key components, and they are all quite large. You can imagine which means your initial investment will likely be a bit costly.

Again, however, you intend with this investment paying off. You're going to be investing in a mixing system plus a control system. You're also going to be purchasing a drying system and weighing system. And then finally, other two key components are a dust removal system as well as a packaging system. There's much to these machines!